Rostec mounts 3D print for air engines

The additive technologies center of Rostec launched 24 new instruments to 3D print aircraft engine components.

Follow Air Recognition on Google News at this link

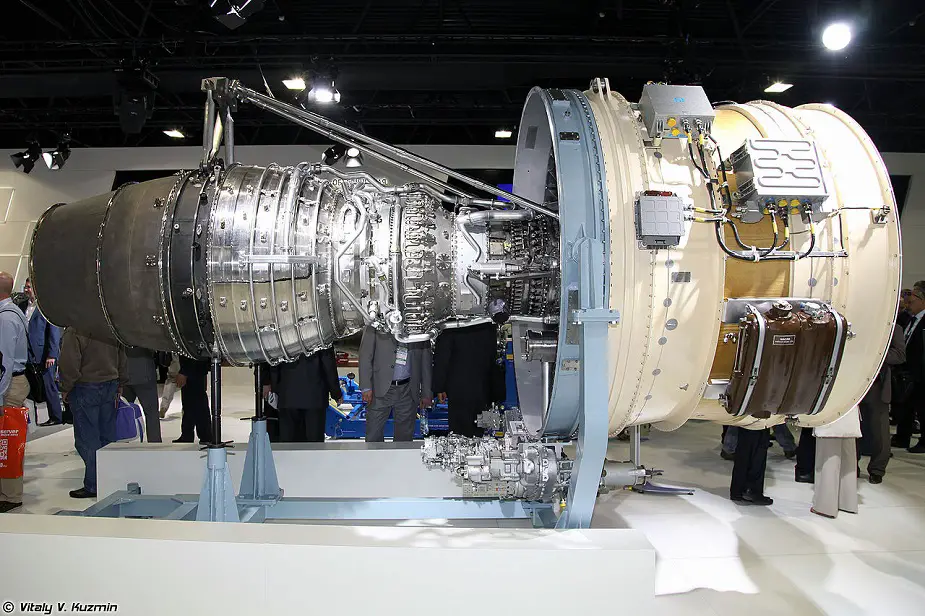

Side view of PD-14 engine (Picture source: Vitaly V. Kuzmin)

Side view of PD-14 engine (Picture source: Vitaly V. Kuzmin)

The new equipment will increase production 261 percent in 2021. The center also obtained the status of a full-cycle service company to launch batch production of units for the latest Russian aircraft engines, including PD-14, Rostec said.

The new equipment includes SLM metal powder print. The technology melts particles and creates monolith units. It minimizes the risk of micro cracks and increases the strength of products against traditional casting processes.

The center is introducing a laser with the biggest production space in Russia.

“Additive technologies decrease costs and weight 50 percent, but maintain strength characteristics. The use of 3D-printed components in aircraft engines accelerates design and production and improves characteristics. The additive technologies center is among twenty major enterprises in the world. The new equipment increased its capacity 261 percent. The center acquired the status of a full-cycle service company. The new capacities will produce components of the latest Russian aircraft engines, including PD-14 engines,” center CEO Vladislav Kochkurov said.

The center is the leading Russian additive enterprise and the sole full-cycle producer. It made units for demonstrators of PD-35, VK-650V and VK-1600V engines, body units of Ansat-M helicopter and others.

© Copyright 2021 TASS. All rights reserved. This material may not be published, broadcast, rewritten or redistributed.