Breaking News

Focus: Türkiye's Quest for Strategic Independence with Roketsan Reactive Armor on Altay Tanks.

Türkiye is positioning itself as a key player in the field of armored defense technologies, thanks to the integration of Roketsan's reactive armor on its main battle tanks, the Altay. By investing in this advanced protection, the country is not only enhancing its deterrence capabilities but also demonstrating a commitment to strategic independence in defense. This technological advancement, now installed in series on the Altay tanks, paves the way for a new era for the Turkish armed forces, with potential repercussions on the international market. Follow Army Recognition on Google News at this link

Equipped with a 120mm smoothbore gun, the Altay MBT can engage moving targets with high precision, thanks to its Volkan II fire control system. (Picture source: BMC)

The Altay main battle tank, produced by BMC, is the result of a long development process that began in the 2000s. Intended to replace older models in service within the Turkish armed forces, the Altay embodies modernity with its impressive capabilities. Equipped with a 120mm smoothbore gun, this tank can engage moving targets with high precision, thanks to its Volkan II fire control system. Developed by Aselsan, this system allows for rapid and accurate target acquisition, even in challenging combat conditions.

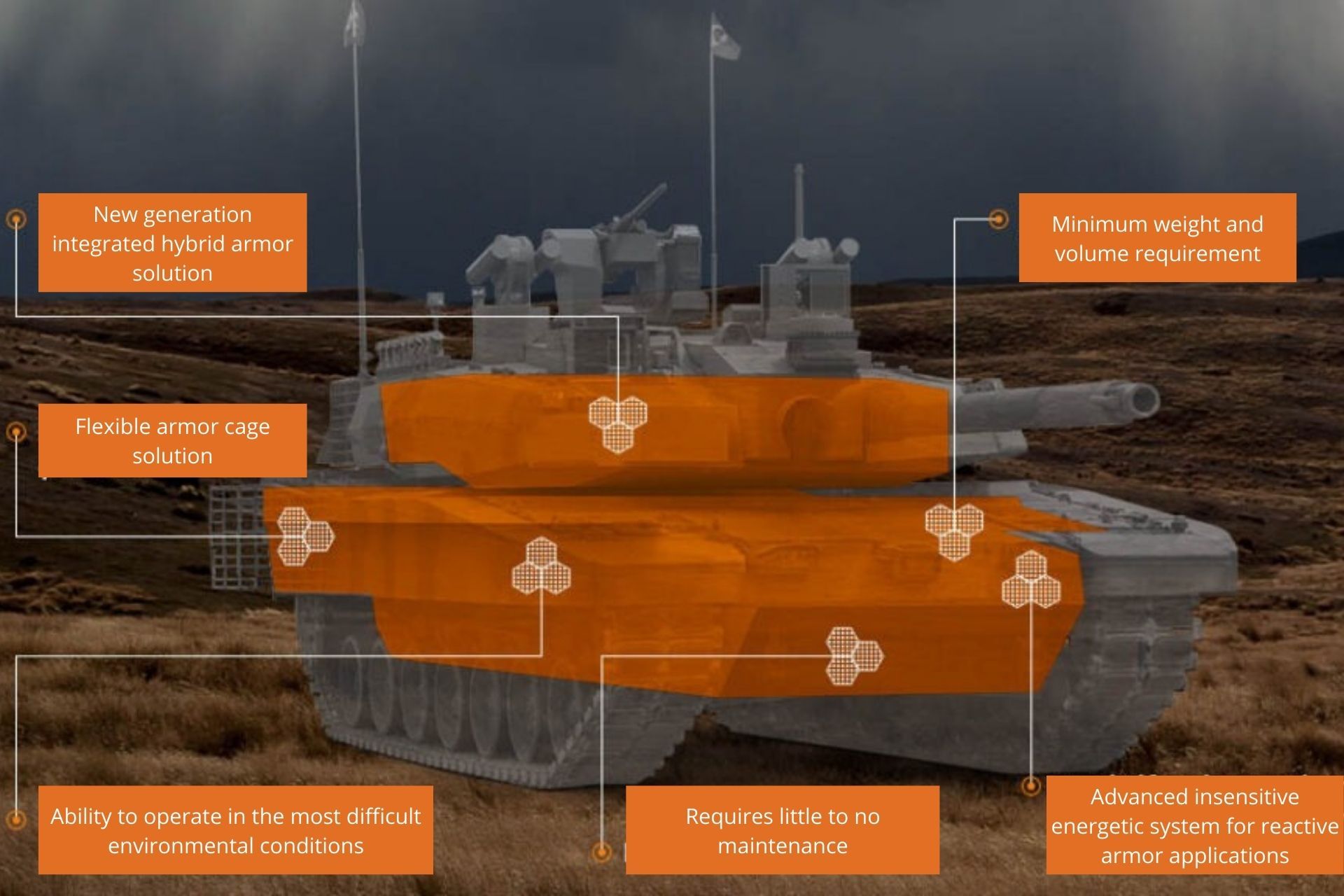

The Altay tank also stands out for its advanced protection. In addition to its modular composite armor designed to withstand a wide range of ballistic threats, the Altay integrates the AKKOR active protection system. Developed locally, this system is capable of detecting and intercepting imminent threats, such as anti-tank missiles. However, it is the reactive armor provided by Roketsan that is drawing attention today, due to its ability to counter the most sophisticated attacks.

Roketsan's reactive armor operates on the principle of controlled movement of metal plates triggered by an explosion, designed to disrupt the formation of the metal jet generated by a HEAT (High-Explosive Anti-Tank) projectile. This technology, although complex, offers significant protection against threats that could otherwise penetrate traditional armor. Upon impact, the explosive placed between the armor's metal plates detonates, propelling the plates to break or deflect the metal jet before it can pierce the tank's main armor.

The development of reactive armor in Türkiye began with strong international collaboration, notably with South Korea. Hyundai Rotem, a global leader in armored vehicle design, played a crucial role by sharing its expertise with Turkish engineers. This cooperation allowed Roketsan to design a composite armor inspired by the South Korean DSAP, used on the K2 Black Panther. However, the Turkish version was adapted to meet the specific needs of Turkish military operations, particularly in terms of climate and threat types.

Roketsan's reactive armor operates on the principle of controlled movement of metal plates triggered by an explosion, designed to disrupt the formation of the metal jet generated by a HEAT (High-Explosive Anti-Tank) projectile (Picture source: Roketsan)

It is important to note that reactive armor can be classified into two major categories: ERA (Explosive Reactive Armor) and NERA (Non-Explosive Reactive Armor). ERA, which uses explosives to deflect the metal jets from shaped charges, is the most common form of reactive armor. In contrast, NERA, which relies on non-explosive but reactive materials, represents a more recent and innovative alternative. This latter type of reactive armor is particularly interesting for theaters of operation where the use of explosives could pose additional risks, such as in urban or densely populated areas.

The development of these armor technologies aligns with a global trend where tank protection is becoming increasingly complex. Modern tanks face multiple threats, ranging from anti-tank missiles to kinetic energy penetrators and drones. While reactive armor is highly effective against shaped charges, it is less effective against kinetic energy penetrators like APFSDS (Armour-Piercing Fin-Stabilized Discarding Sabot). This is why armor designers, like Roketsan, are constantly working to improve their systems to offer multi-directional protection.

Turkey's strategic choice to develop its own reactive armor technologies is driven by several factors. Firstly, it strengthens the country's autonomy in defense by reducing dependence on imports of critical systems. Secondly, it offers Türkiye a competitive advantage in the international arms market, where demand for advanced protection systems continues to grow. Comparisons with foreign systems, such as Russia's Kontakt-5 or Israel's Reactive Armor, show that Roketsan's armor is on par with its competitors. Indeed, Turkish systems provide effective protection against contemporary threats while being adaptable to various types of vehicles and missions.

Beyond Türkiye's borders, Roketsan's reactive armor could attract interest from several countries looking to modernize their tank fleets. Nations like Qatar, which has already shown interest in Turkish military equipment, as well as African and Asian countries, could become potential customers. Türkiye's ability to produce these systems on a large scale and integrate them effectively on different tank models could position the country as a major supplier in this segment of the defense market.

The introduction of Roketsan's reactive armor on Altay tanks represents a decisive advancement for Türkiye's defensive capabilities. As the country accelerates the production of these tanks, the question of their export becomes increasingly relevant. With evolving threats and growing demand for advanced protection solutions, it is likely that Turkish reactive armor will find markets internationally.

The cooperation with Hyundai Rotem allowed Roketsan to design a composite armor inspired by the South Korean DSAP, used on the K2 Black Panther (Picture source: Rokestan)