Picatinny Arsenal to boost range and power of artillery with an electrically-responsive method 21611153

|

|

|||

|

Defense and Security equipment - United States

|

|||

|

|

|||

| Picatinny Arsenal to boost range and power of artillery with an electrically-responsive method | |||

|

If, in the words of Napoleon, “God fights on the side with the best artillery,” Picatinny Arsenal engineers are improving artillery to the point that there should be no doubt as to which side should be favored. The US research team seeks to extend the range, power and versatility of artillery by using an “electrically-responsive” method to control energetic materials such as artillery propellants.

|

|||

|

|

|||

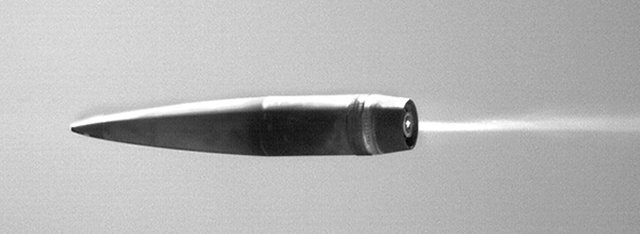

The XM1113 extended range artillery, shown here at a range demonstration, uses a rocket-assist motor. Researchers at Picatinny Arsenal are exploring ways to use electrical charges to give warfighters more control to increase the range and burn rate of rocket propellants The XM1113 extended range artillery, shown here at a range demonstration, uses a rocket-assist motor. Researchers at Picatinny Arsenal are exploring ways to use electrical charges to give warfighters more control to increase the range and burn rate of rocket propellants(Credit: Picatinny Arsenal) |

|||

|

|

|||

|

“Electrically-responsive” means that the materials are controlled by electricity. “Energetic materials” are items such as explosives, propellants and pyrotechnics.

“If you can control the burn rate and energy output of a propellant with electric voltage, this opens a whole new capability,” explained David Thompson, a chemical engineer and member of the research team. “Right now, we’re considering it (electrically-responsive energetics) for rocket propellants found in extended range artillery rounds.” Thompson and his fellow researchers work at the Armament Research, Development and Engineering Center (ARDEC) at Picatinny Arsenal. ARDEC is part of the U.S. Army Research, Development and Engineering Command at Aberdeen Proving Ground, Maryland. The US Army uses artillery rounds that have two different types of motors for their extended range propellants. “One is called the base bleed motor, which gets some extended range over a normal round and burns right out of gun,” said Thompson. “The other is a rocket assist motor, which doesn’t burn until it gets the top of its flight, before it boosts and increases the velocity of the projectile. “With electric voltage, you could use one motor that does both,” Thompson added. “You could create a low-voltage, right out of the gun, and get that base-bleed effect, and then hit it with a high voltage and get the rocket-assist effect, ultimately increasing the range over that which either motor can provide on its own.” Members of Picatinny’s energetics team are Kimberly Chung, Eugene Rozumov, David Thompson, Dana Kaminsky, George Fischer and Kelley Caflin. Their research is an Army Science and Technology funded project. Currently, one item that uses a base-bleed motor is the XM1128, an artillery round that can achieve a maximum range of 30 kilometers. Another device that uses a rocket-assist motor is the XM1113, an artillery round that can achieve a maximum range of 40 kilometers. To compare, that means that both the XM1128 and XM1113 can travel the length of more than 250 football fields, and that artillery rounds using electric energetics would potentially be able to travel farther. The XM1128 and XM1113 are both managed by the Project Manager Combat Ammunition Systems, or PM-CAS, which is part of the Program Executive Office for Ammunition at Picatinny. Increasing the propellant’s extended range is simply one benefit of this project, though. The team’s ultimate goal is to provide the warfighter more control over the rocket propellant in the same way we can flick a switch to turn on the light. In turn, this could increase not only the propellant’s range and burn rate, but also its power and speed. The result? A versatile weapon with extended range and a consistent, powerful performance. “When you fire a gun propellant at some tank, the performance differs in different temperatures,” explained Thompson. “For example, the round’s velocity is different when it’s fired in a hot temperature than in a colder temperature. “So, the troops have their manual that basically says ‘If you put your gun at this angle, and fire this charge, it will get this much velocity and you’ll hit the target.’ But, because the propellant’s effectiveness can change in different environments, they have to compensate for temperature. “Our idea was to use an electrical igniter with a propellant that we can control, allowing us to burn the propellant at different speeds and rates,” continued Thompson. “We want to use the igniter to improve the round’s performance in the cold, and maintain its performance in the heat, but also ensure that the performance is identical throughout. This way, the troops can fire the same thing and get a consistent result no matter what.” Their project started in 2009 after ARDEC personnel saw a presentation by Digital Solid State Propulsion, Inc. (DSSP), a contracting company in Las Vegas, Nevada, that commercializes green and solid energetic materials. During the presentation, DSSP demonstrated an energetic that could be controlled with electricity by using a compound known as hydroxylammonium nitrate (HAN), an inorganic salt. DSSP’s HAN-based formulation is a plastisol, a material that flows like a liquid but can be converted into a solid when heated. Inspired by the demonstration, ARDEC personnel returned to Picatinny and assembled a team to determine if a similar material could be integrated into a weapon system. Initially, the team worked with DSSP and tested its formula, as well as modified samples of that formula, as replacements for 120mm tank igniters, which are already electrically initiated. It takes multiple steps to activate a tank igniter. Before it sets-off, a bridge wire heats up which causes the primer material burn. Then it expels gases into the igniter’s body, burns its fill, and explodes. However, with electrically-responsive energetics, the ignition could potentially be done in a single step. “They (DSSP) had a base formula that we knew that they could turn off for sure,” said Kimberly Chung, a chemical engineer. “But, when we tested it, we were afraid that that formula didn’t have enough energy. So, we went to the second candidate, one that has metal added to it, which makes the burning a little more vigorous. But then, we couldn’t turn that one off. That was our trade off: more energy that we couldn’t control.” During proof-of-concept tests, a sample of the different formulas were connected to a power supply and hit with electric voltage. The team also performed thermal stability tests. “All of our energetics have to go through a thermal stability test, where they measure how much gas comes off our energetics. It will tell you things like…if the energetic will be stable sitting in the field for years,” said Thompson. “It’s a regulation and they have to pass this test in order for us to use them.” Still, the initial tests demonstrated that the contractor’s material produced too much gas and remained unstable. The tests also showed that the material had compatibility issues with the weapon’s metals. “We finished working with DSSP in 2013. We simply couldn’t continue working with their material,” said Chung. “But, we really liked their idea of electrical initiation and energetic materials, so we became internally funded to do our own work.” Since the internal funding, the team has switched its focus from tank igniters to rocket motors, which showed better results with the modified formulations. However, the new formulations are based on the standard rocket propellant formulations. The new formulations have undergone similar proof-of-concept and thermal stability tests that were previously provided. But, only one formulation has shown success with both tests. The other materials have too high resistivity for a useful current to flow with typically available voltages. “With the newer material, you apply power and the material starts to burn,” said Chung. “There is a minimum amount of energy that needs to be put in for it to burn.” Chung said one main issue with this project is that many rocket artillery rounds don’t have an imbedded electrical source. This means that the team will need to find a power source to ignite their energetics. The team is also uncertain about how much of the material’s burn rate they are controlling or if they’re only capable of turning it on and off. However, the team has begun mixing and curing studies of their successful sample. Curing is a process in which a material is converted from a liquid to a solid (such as a thermoplastic). While the team has successfully cured the material, in some cases the cured material does not always ignite. “Usually, you make a propellant formulation and mix them. When you mix them, they’re soft and fluid, like play dough, and you can pour it into a mold. Then, you put it in an oven and cure it and it gets hard,” said Thompson. “Right now, the mixture seems to work a lot better uncured, which probably won’t work in a projectile because the material is too soft—it probably won’t survive gun launch.” Testing and evaluation continues. But the research team foresees positive outcomes, including lower costs. “With rocket propellants, it (electrically-responsive energetics) would not cost any more than the propellants that we have fielded now,” said Thompson. “You’re adding that extra capability of turning it on or off and controlling its burn rate in flight, which now you can’t do at all.” |

|||