Stoof International armoured vehicles with bullet-proof windows Saint-Gobain Sully 0806124

| a | |||

| Interview

with Peter Mead from Stoof International on the armoured vehicle market

trends |

|||

| Friday , June 8, 2012, 09:51 AM | |||

| Interview with Peter Mead from Stoof International on the armoured vehicle market trends: | |||

For most people the words “armoured vehicle” conjures up,

in the first instant an image of a military vehicle; immediately followed

by a black limousine and reporters in front of a prestigious building

for a G20 meeting. Then of course a rich Arabic sheikh, high risk businessman,

Royal family, movie star… Armoured vehicles were used by media teams in places like Kosovo and also on a longer term basis in Israel and the occupied territories reporting on the never ending conflict. VIP’s and celebrities are always associated with such vehicles, but in reality they account for only a small amount of the actual market. The major share of armoured cars built on a civilian basis comes as Toyota Land Cruisers designated for conflict territories. Doctors without Borders, UNICEF, Red Cross, diplomats and civilian organisations all need to move from point A to point B to fulfil their well-intentioned peaceful tasks, the rebuilding process – but in the eyes of the aggressors – they ALL are legitimate targets. Some stories started to appear in the news concerning the malfunction of armoured vehicles in recent years. This is the industry nobody spoke about openly because of security reasons, i.e. particular information should not be accessible to terrorists targeting these vehicles. However nowadays one can find in-depth information about the armouring process, technology and features of cars which should protect lives. Army Recognition met with Peter Mead, International Sales Director at Stoof International, a leader in armoured vehicles based in Germany. We asked him about his opinion on the evolving armoured vehicles market. |

|||

Armoured

Hyundai Equus Limousine with Saint-Gobain Sully glasses Armoured

Hyundai Equus Limousine with Saint-Gobain Sully glasses |

|||

Army

Recognition (AR): Armoured cars industry has always been highly confidential

and closed to the public. However nowadays one can encounter many technical

details openly discussed and demonstrated through videos and other sources

on the internet. What is the reason of this industry change? |

|||

Peter

Mead (PM): Traditionally most of the armoured vehicles were being

built within European region or the United States. Due to the increased

demand attributed to recent military operations in Afghanistan, Iraq and

other conflict territories, many new companies, suppliers of armoured

vehicles sprang up like mushrooms over night throughout the Middle East

/ Gulf regions taking advantage of the industrial Free Zone benefits in

close proximity to the troubled regions and cheap foreign labour. In fact, it is no easy undertaking to apply over a 2000 kg of ballistic steel and glass into a civilian purpose motor vehicle so that it can operate efficiently and also maintain its weight distribution and handling capabilities. Armouring of vehicles is hands-on skilled craftsmanship in the true time-honoured manner. Stoof International Germany was one of the few earlier companies that entered the market to meet the immediate demands for those organisations with boots on the ground. Since then the industry has been reshaped and price based competition emerged. Armoured vehicles were being literally thrown together within the zones with prices as much as 40% below, and completed within days instead of weeks or months. Variety of prices along with evolving customer behaviour has reshaped the demand for these vehicles. With prices ranging from 80.000 € to 400.000 € per unit a lot of money is at stake. As a consequence with as little as 5 to 10 units you are already talking about millions of Euros. But like most things in life the end-user will get what they pay for, and with such drastic differences, there has to be some dramatic shortcuts being made. Low cost armoured vehicles are delivered without reinforced hinges and sufficient overlaps – important features to prevent projectiles from entering the cabin through angles. Some vehicles even have plastic wedges screwed into the doors sills to prevent the doors from sagging too far, preventing them from closing. There are some suppliers who simply apply 70-78 mm bullet-resistant glass to a regular vehicle without specific frames and sufficient overlaps. In the event of an explosion the whole ballistic glass piece is pushed into the vehicle. Another issue is the certification of the vehicle. |

|||

Armoured vehicle with Saint-Gobain Sully glasses, was hit by a vehicle born improvised explosive device (VBIED) in Afghanistan on a motorbike. Both passengers survived and drove away from the incident. |

|||

AR:

Since international organisations and diplomatic missions are major customers

on this market in terms of quantity, do you think there is a risk that

this price competition will affect the quality and the reliability of

armoured vehicles traded worldwide? |

|||

PM:

Organizations like the United Nations will have to put the procurement

through a tender process; a tedious, complicated procedure. Particularly

when describing the specifications and trying to cover all the important

points, most organisations will have a standard tender format that they

try to adapt to incorporate demands. Base vehicles and protection specifications

are in some cases put together with valid experience field input. In other

words information passed back from the end-users: staff on the ground.

Some organisations send inspectors or have visited the production plant

before hand. However in a majority of cases only the word of the supplier

or seller is taken. In many cases numerous tender specifications are a

simple “copy & paste” from previous suppliers offers.

Procurement clerks / assistants / officers are assigned a task whereby

they are to simply tick the boxes. For some unimaginative reason ex-service

men / security type operatives – Protective Services Detail (PSD)

with valuable field experience, never seem to be directly involved when

it comes to actual vehicle specifications. Armoured vehicles are being used by civilian organisations and procured by civilians despite the security / military aspect that come with them. Whether civilian or military the attacks carried out on them are the same. So how can it be that a procurement official who has no knowledge of anything connected with let’s say the military, security or police type service; or even vehicles as a whole, can ascertain or make a decision on what is best for others to trust their lives with? If a base vehicle costs 50.000 € and the materials like bullet-resistant glass, armoured steel and important features alone cost 20.000 €, what type of an armoured vehicle, do they seriously think will the end-user be getting for paying 79.000 € and less? The opportunity rarely exists to explain or bring over the differences in quality or design which in consequence will save the organisations money, time, financial and logistical headaches. And in a worst case scenario, people’s lives! Many “Invitation to Bid” (ITB’s) or “Request for Quotations” (RFQ’s) have simple check lists. A cross or tick in the appropriate box is all that is required. This gives the opportunity to participant companies to “reformulate” requests and “to package” the product in order to make it relevant to requirements set by tenders. Armoured vehicles are sold to agencies by third parties, consulting companies and even by mobile telephone suppliers or soft drinks distributors that registered themselves for the tender. They simply register and then send in an offer after they have surfed through the Internet. The industrial free zones product will be cheap enough for them to add on a commission price. And as a result the company with the lowest price wins the bid. |

|||

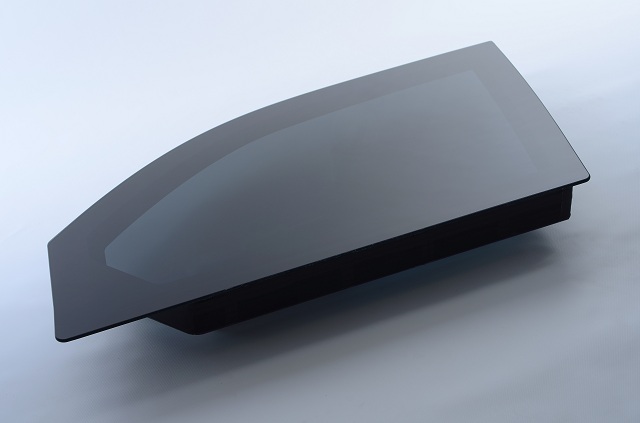

Bullet-resistant glass from Saint-Gobain Sully; Br7 level; tinted side-window for SUV |

|||

| AR: What will be the response from companies delivering reliable armoured vehicles? | |||

PM:

We do not change our strategy of delivering premium quality and

cooperate with high quality suppliers. For example Saint-Gobain

Sully, company belonging to Saint-Gobain Group having glass know-how

of more than 3 centuries, is our supplier of bullet-resistant glass –

one of the most important components of armouring. Manufacturing, in-house

testing and R&D is done in France in Saint-Gobain Sully facilities

with highly skilled labour. The company possesses all international certificates

available worldwide and has been our reliable supplier of bullet-resistant

glass since many years ago. We are confident that our armoured vehicle

with Saint-Gobain Sully glasses will withstand to relevant ammunition

on the field. We at Stoof International, with our suppliers

define innovative business models, lean management practices and ways

to minimize production costs by not compromising on quality. Optimised operations result in competitive prices for components we purchase and as a whole we deliver the full package of armouring by ensuring the durability and reliability of vehicles devoted to protect people’s lives. As a result only customers like, for example, European governments, who test vehicles by themselves pay for relevant performance and choose reliable suppliers. These customers represent less than 30% of the market. However, recent practice has shown that low-cost vehicles spend more time in garage for repair than on the field and as a result the life-cycle cost of low-cost vehicles is not as low as considered. But after all, armoured vehicle should protect! And the life of many people sitting in it depends on the quality of armouring. |

|||

Armoured Hyundai Equus Limousine with Saint-Gobain Sully glasses |

|||

| AR: What are the benefits of using skilled and premium suppliers like Saint-Gobain Sully? | |||

PM:

It is imperative that first-rate ballistic glass is installed in the vehicle

from the offset. Vehicles are dispatched to far away and dangerous regions

of the world, following up on potential glass deficiencies or defects

can be an extremely costly and timely experience regarding after-sales

support - it better to get it right first time in the long run. Good quality

glass of course only comes about with experience and Saint-Gobain Sully

has a long and proven track record. When delivered vehicles have in been

on field assignment for a few months travelling across ough terrain with

souring high temperatures this is where it counts; delaminating, poor

optical vision and cracks are not the feedback an armourer wants to hear

once the vehicles are so far away. Saint-Gobain Sully quality pays for

itself over an extended period of years in our vehicles, and not just

for a year or so as others have discovered when going for the so called

much cheaper option. |

|||