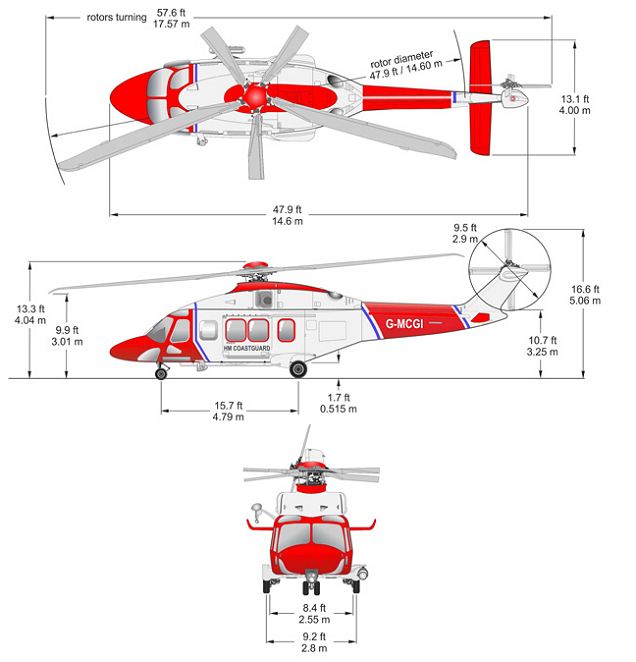

AW189 Agusta Westland

| a | ||||||||||||||||||||||

|

AW189 AgustaWestland twin-engine medium helicopter

|

||||||||||||||||||||||

|

||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

The AW189 is a twin-engined, medium-lift helicopter currently under development by the Italian Aviation Company AgustaWestland, and is derived from the AW149. The new AW189 model was announced by AgustaWestland at the Paris International Air Show on 20 June 2011. The company plans to have the helicopter certified by 2013 and in service in 2014. The new state-of-the-art 8 tonne class AW189 is designed in answer to the growing market demand for a versatile, affordable, multirole helicopter. Optimised to operate in harsh conditions undertaking long range, deep water missions typical of the Offshore industry, the AW189 combines high performance, competitive operating economics and superior passenger comfort. The AW189 twin engine 8-tonne class helicopter successfully completed its maiden flight, December 22, 2011. With five prototypes now in flight totalling over 800 hours and contracts signed for more than 60 units including firm orders and options, the AW189 programme is set to achieve certification in the second half of 2013. The twin engine AW189 helicopter is optimised for the long range offshore transport and SAR missions as well as parapublic and VIP transport roles. In december 2012, AgustaWestland has announced that Azerbaijan Airlines has ordered two AW189 to be used for offshore transport operations. In March 2013, AgustaWestland has signed a deal with Malaysia's Weststar Aviation service two AW189 helicopters.

|

||||||||||||||||||||||

| Main Variants: | ||||||||||||||||||||||

|

-

|

||||||||||||||||||||||

| Technical Data | ||||||||||||||||||||||

| Design | ||||||||||||||||||||||

|

The AW189 meets and exceeds the airworthiness requirements of the most recent EASA / FAA amendments in the transport category (Part 29) and is qualified to fulfil the most stringent guidelines of the major oil & gas companies.High safety is achieved on the AW189 through a series of design features. Structural crashworthiness has been a priority in the design of the airframe, fuel system and seats. A reinforced windscreen and optimum positioning of critical controls mitigates the consequences of a birdstrike. Cabin layout options include a range in seat density up to 18 seats, and Medevac & SAR configurations. Modular fuel systems, quick to fit and remove, ensure the optimum mission specific trade off between passengers and distance can be achieved.Large sliding doors lend the AW189 to both superior egress for passengers and the efficient loading of cargo pallets. Hook load capacity (2722 kg / 6000 lb) extends the mission flexibility of the AW189 to roles such as fire-fighting and external cargo lift.

|

||||||||||||||||||||||

| Avionics | ||||||||||||||||||||||

|

Cockpit design of AW189 incorporating the latest in advanced situational awareness technologies (HTAWS, TCAS II) reduces crew workload. CHOICEExceptional external visibility and the deployment of the latest in avionics technology make the AW189 the pilot’s choice. The open architecture avionics suite includes full digital glass cockpit with four 8” x 10” displays (AMLCD), a 4-axis dual-duplex digital automatic flight control system (DAFCS) and dual Flight Management System (FMS). All contribute to minimising pilot workload during VFR / IFR flight. Single pilot IFR certification is a design objective. The avionics suite is suitable for the NextGen satellite-based IFR navigation (RNAV / RNP, vertical navigation and precision approaches) and advanced communication and surveillance requirements (ADS-B). The AW189 sets new standards in situational awareness in low visibility flying conditions. The optional Synthetic Vision System emulates the surrounding topography to enhance terrain and obstacle avoidance while the optional Enhanced Vision System sees through darkness, smoke, dusk and light fog further improving operational safety.The integrated AW189 avionics system performs Point-In-Space (PINS) and Offshore approach procedures.

|

||||||||||||||||||||||

| Propulsion | ||||||||||||||||||||||

|

The AW189 is powered by two General Electric CT7-2E1 turboshaft engine, 1,492 kW (2,000 hp) each each. The AW189 main gearbox benefits from a 30 min ‘dry-run’ capability and Cat. A, PC1 / PC2e performance allow take offs and landings with high payloads and superior safety margins in the challenging world-wide locations associated with Offshore operations.

|

||||||||||||||||||||||

| Mission capabilities | ||||||||||||||||||||||

|

All Weather Day and Night, VFR / IFR certified, the AW189 will operate seamlessly in the harsh conditions prevalent in Offshore operations. The spacious cabin is configured with 16 seats as standard. Seating options include a high density 18 seat layout or an ultra long range 12 seat configuration. High cruising speed and a very high payload due to a highly efficient rotor system, together with superior O.E.I capability, make the AW189 ideally suited to the safest Offshore operations with the lowest operational costs. Next Generation avionics expands further operational capabilities, contributing to safety by enhancing situational awareness and reducing crew workload.

Ideal for day / night airborne parapublic operations even in harsh conditions, the AW189 may be configured with a wide range of advanced sensors, role and communication equipment. The generous cabin space, excellent accessibility and flexibility in seating configuration together with quickly removable options such as a fast rope system and cargo hook makes the AW189 particularly suited to a variety of special forces and utility operations. |

||||||||||||||||||||||

| Specifications | ||||||||||||||||||||||

|

||||||||||||||||||||||

|

||||||||||||||||||||||

|

||||||||||||||||||||||