Breaking news

MTL Group unveils new add-on armour branded IMPAS LIEE & ADVANCE at AUSA 2011.

| a | |||

|

|||

Daily

News AUSA 2011 United States Army Annual Meeting & Exposition Washington D.C., United States 10 - 12 October 2011 |

|||

MTL Group at AUSA 2011 |

|||

| Tuesday, October 11, 2011, 06:49 AM | |||

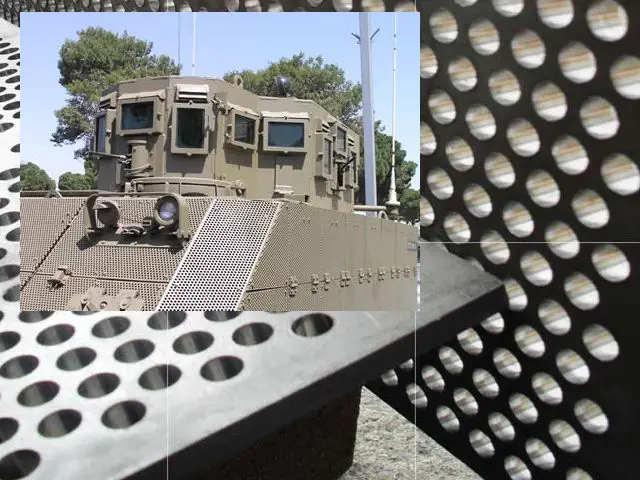

| MTL Group unveils new add-on armour branded IMPAS LIEE & ADVANCE at AUSA 2011 | |||

Armour

plate processor MTL Group (UK), will be showcasing their new add on armour

branded IMPAS LITE and IMPAS ADVANCE this month at AUSA 2011 (Washington

D.C). IMPAS which stands for Interchangeable Modular Perforated Armour

System is a cost effective alternative light weight solution to composite

and ceramic add on armour with greater flexibility and better multi-hit

capabilities. MTL Group will be exhibiting at AUSA on the UK Pavilion (ADS) on Stand 8233. |

|||

|

|||

| Defence Sales Manager Simon Hurst said: IMPAS is an innovative state of the art product which is suitable for both RHA and aluminium hulls. One of the key benefits is that the solution is a low cost lightweight armour that can be rapidly fitted to any vehicle platform. We have identified the USA as a key market in which MTL Group can provide a high quality vehicle protection system at affordable prices. IMPAS LITE AND IMPAS ADVANCE offer an effective alternative lightweight solution to composites ceramics for Stanag Level 1, 2 and 3 protections. IMPAS has been used for many international military upgrade programmes including the M577 and Ridgeback. MTL Group will also be showcasing its Design for Manufacture (DFM) service. An example of this can be seen on a blast floor which is displayed at AUSA and has been manufactured in one piece using the world?s largest robotic press. DFM is a service MTL Group offer where we work with customers to identify the 3 core objectives which are lower weight, lower manufacturing cost and improved protection, Hurst said. MTL

Group is a global supplier of parts manufactured from armour in both steel

and aluminium offering a full turnkey process ranging from cut and pressed

armour kits up to fully fabricated vehicle hulls/cabs. |

|||