Breaking news

Testing Times Ahead for the Royal Navy F-35B Lightning II Fighter.

| 2016

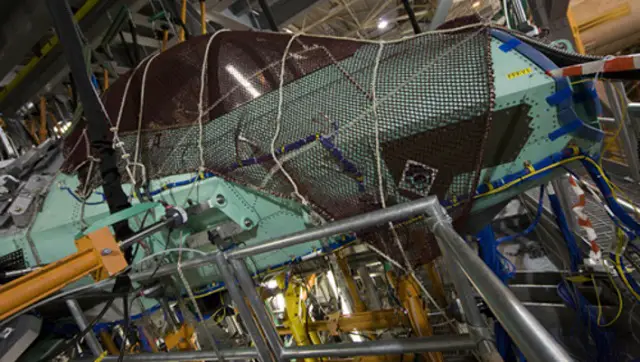

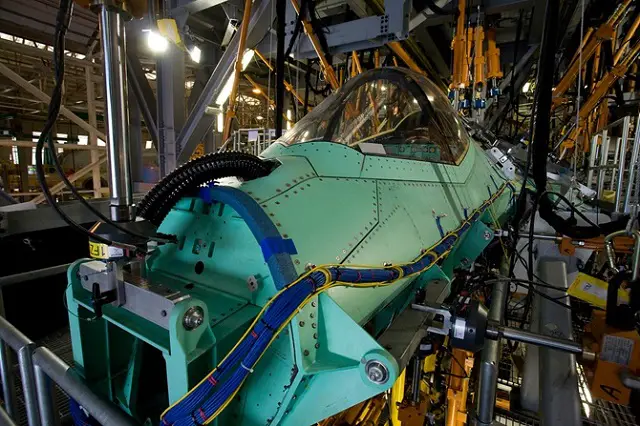

The engineers use a special 350-tonne test rig, which has been built to ‘fly’ the F-35 through a series of scenarios. Picture: BAE Systems |

|||

The engineers

use a special 350-tonne test rig, which has been built to ‘fly’

the F-35 through a series of scenarios. More than 20 miles of wiring,

2,500 strain gauges and 160 loading actuators are designed to subject

the aircraft to a range of loads that it could typically encounter when

airborne. “We’ve pushed the testing to the limits, ensuring that the F-35 will fly safely and effectively throughout its lifetime of service,” explained Andy Prendergast, operations manager for structural and dynamic testing “Reaching two complete lifetimes of testing is an important milestone for our structural test facility at Brough, and demonstrates the proven endurance of the F-35 airframe. We will further qualify this by starting a third lifetime of testing.” His team has rigorously tested a dozen aircraft types over the past 40 years from the legendary Buccaneer and Harrier right up to the Eurofighter. Fifteen per cent of each F-35 is produced in the UK, with BAE manufacturing the jet’s rear fuselage, vertical and horizontal tails and wing tips and numerous other elements of British industry bringing more to the complex aircraft. BAE are also responsible for the fuel system, crew escape, life support and ensuring the Lightning II operates seamlessly with the two new carriers. |

|||